by Larry Hawkins, PAS

2021 has a brought some good news, but a problem is looming for dairy farmers in some parts of the country. I am referring to forage shortages before new crop can be harvested and cured. If you see that you will be running out of corn silage before your usual March 2022 silo opening time, here are a few things to consider.

How Corn Silage Changes During Fermentation

It is well known most corn silages need some time in the bunker to become as good as it can be. Switching to “green” 2021 corn silage from 2020 well-cured silage is a recipe for an unneeded drop in milk.

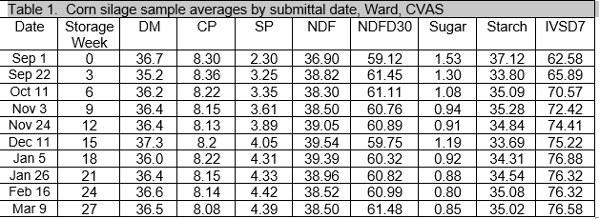

Some research done several years ago by Dr. Ralph Ward; President of Cumberland Valley Analytical Services (CVAS) shows the evidence in the clearest way. CVAS collected their data from all corn silage samples submitted to their lab. They then divided the data by submittal dates into to three-week periods starting from September 1st . These first samples would be very green and then become fully fermented in this period. All values of the samples were averaged for each three-week period until March 30th of the following year. Partial results are shown on Table 1.

The idea was to show which metrics were affected by fermentation. Which metrics changed and which were unaffected? If they changed, did they go up or down? I greatly distilled the list since every parameter which CVAS analyzes was in their spreadsheet. (The dirty little secret in feed testing is every parameter gets tested on every sample, but you only see the ones you pay for!). Obviously, a metric going up or down and even staying the same is does not mean anything until the metric is understood. On the complete spreadsheet provided at the time by CVAS, the vast majority of measurements remained relatively unaffected. One notable metric not shown on Table 1 but immaterial to our discussion here and which did change was pH – which predictably went down over the seven-month period as fermentation was completed.

An important point here is the majority of all corn is of a flinty or vitreous variety.

Dry Matter, Crude Protein, Soluble Protein NDF, and NDFD30

Looking at the columns from left to right, shows that dry matter (DM) over the time period and with tens of thousands of data points stayed the same and, of course, we would not expect storage time to affect it. This simply shows that the average DM was about what we would expect it to be.

Also, crude protein (CP), as expected, remained unchanged. Soluble protein (SP) however, again as expected increased significantly due to proteolysis or breakdown of the protein structure. Neutral detergent fiber (NDF) throughout the test period also was unaffected by the fermentation.

The first surprise was the fact that fermentation had little effect on NDFD30! A lot of preservative salespeople are probably disappointed (Spoiler alert, I am a big supporter of preservatives.) I would surmise most of these samples were inoculated. Did the preservatives do anything – absolutely, they did a lot, but that is another story!

Sugar, Starch and Starch Availability

Once more, sugar followed the expected course and declined during fermentation as the sugars were converted to lactic acid and other VFAs. Starch percentages also remained unaffected by fermentation.

The big difference showed up in the Starch Availability or IVSD7 numbers as the IVSD7 creeped up until the January 7 3-week period, when it got as good as it would ever get. Remember, this table represented tens of thousands of samples submitted to CVAS.

What About Floury Starch?

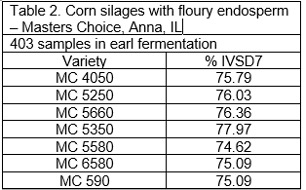

In the same year as the above survey was done, Masters Choice (MC), Anna, IL submitted over 400 plot samples to CVAS for analysis. Masters Choice was the first promoter and provider of corn with the floury endosperm. These samples were submitted to the lab without ever having been in a silo and very early in their fermentation period. The IVSD7 numbers for a number of floury varieties are shown in Table 2.

Ready to go at the Start!

The neat thing about these floury starch samples is they in about their first month of fermentation had already reached as good a IVSD7 level in about a month and may have been that good even earlier as the conventional samples after 4 to 5 months in the bunkers. When they reached this point, they quit getting better. Would the MC samples improve from where they started? Unfortunately, we only had one timepoint for the MC samples. Maybe they would change a little, however they were ready to feed much earlier in the process than the vitreous, flinty type corn silages. This can mean three to four months earlier feeding opportunity with floury corn silages. Definitely a big advantage when you are out of corn silage!

Take Home Lesson

The take home lesson is surely if you need early-harvested corn silage to fill holes in your corn silage supply – plant a floury hybrid. With BMRs, that would be the new Kingfisher BMR and the Unified products from Brevent. In conventional hybrids, there are a number of companies promoting “floury” hybrids but in our experience that term is used too freely. Even the companies like KF and MC that have made this a major part of their selection process have hybrids across a “floury” spectrum. We can help you choose the right products for your system. Just do not waste time getting some lined up to avoid a big fall slump! You can contact us at daniel@forageinnovations.guru or Larry@forageinnovations.guru